|

Often we find that

with most of the various models of Fender’s® tremolo bridges that

utilize a screw-in tremolo arm is that on

occasion the tremolo arm is firm when screwing

in, or it will have loose and tight points

in its rotation as you install it.

Obviously this entirely relies on the fact that you

are installing the correct threaded tremolo

arm in the bridge in question.

This same issue may also arise when mating a

tremolo block to top plate (bridge plate). The

problem lies in how the top plate is aligned

with the tremolo block. Most all of Fender’s®

tremolo bridges that utilize a screw-in

tremolo arm insert the tremolo arm at an approximate

9

degree back angle (except the 6mm Squier®

tremolo arm bridge and some early model MIM

Strat's®) where as the pass-through

hole in the top plate for the tremolo arm is

drilled straight down or perpendicular to

the flat surface of the top plate. Also

there is a very small amount of

miss-alignment of the tremolo arm

pass-through hole in the top plate in

reference to the tremolo arm threads in the

tremolo block and without careful

installation of the top plate to the tremolo

block a tremolo arm may experience

difficulty or tightness when installing.

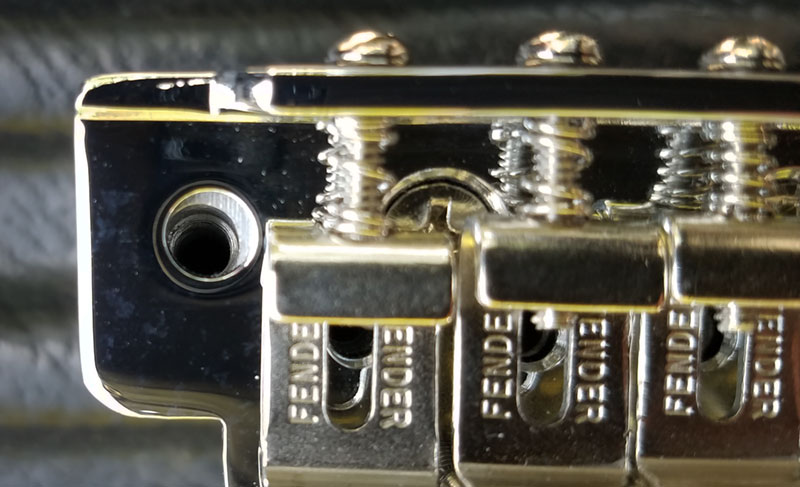

Below is a photograph

a brand new Fender 099-2049-000 vintage

Strat tremolo

bridge assembly right out of the box and you

can clearly see the misalignment of the

tremolo arm pass-through hole in the top

plate in reference to the screw-in threads

in the tremolo block. This is what

causes most of the issues of not being able

to install a tremolo arm into a bridge that

accepts a screw-in tremolo arm. The edge of

the tremolo arm will contact the edge of the

top plates pass-through hole not allowing a

smooth rotation of the tremolo arm straight

down into the threads in the tremolo block

causing friction and typically what happens

is the person screwing in the tremolo arm

will place more leverage on the arm in an

attempt to make the tremolo arm screw in,

then what happens is the tremolo arm is

broke in two right where the threads on the

tremolo arm end and meet the smooth shank

portion of the tremolo arm.

Before performing

any of the adjustment steps below you will

want to make sure the tremolo arm you are

attempting to screw into your tremolo block

is the correct one and will screw into the

bare tremolo block all by itself without the

top plates pass-through hole causing any

interference. Simply screw in the tremolo

arm into the tremolo block without the

top plate installed, just the bare tremolo

block, at this point if it screws in all the

way just fine you'll know that it is the

alignment of the top plate is causing your

interference and tremolo arm insertion

problems. If you are attempting to

screw in the tremolo arm into the bare

tremolo block and it begins to get firm in

its rotation, then STOP, do not go any

further, do not attempt to force it to screw

in, you will damage your tremolo block or

tremolo arm or both. If the tremolo arm does

not want to screw into the bare tremolo

block then you have something going on with

a tremolo arm attachment threading

miss-match or damaged threads in either the

tremolo block or tremolo arm.

Once you've

determined you have the correct tremolo arm

for your bridge but encountered a firm

insertion of your tremolo arm with the top

plate installed a solution to the above

described issue

is to remove the 6 saddles, loosen the 3 top

plate mounting screws, install the tremolo

arm all the way until it stops, then

position the arm where the tip is facing

forward, parallel with the strings as if the

bridge was installed, this is all done while

the top plate is loose, then re-tighten the

3 top plate mounting screws. What this does

is use the tremolo arm as an alignment dowel

to prevent the miss-alignment of the top

plate and tremolo block from becoming an

issue. Typically this will

solve this issue and your tremolo arm will

now install with no (or much less) friction against the

side of the top plate tremolo arm

pass-through hole. This is a common

knowledge characteristic to all those that

build, repair or maintain Strat’s® on a

regular basis and to assume

your bridge is defective because of this

occurrence is simply a lack of understanding

of the tolerances and miss-alignments of the

components involved. All it takes is

0.001” of intrusion of the tremolo arm

pass-through hole in the top plate into the

path of the tremolo arm as it is installed

is more than enough to cause problems, by adjusting the top plate

alignment to remove this 0.001” of intrusion

from the tremolo arm pass-through hole in

the top plate is all that is needs to

entirely resolve the issue.

If you have purchased

a replacement tremolo block for your Strat

and are retaining your

original top plate you may

experience this same issue described above,

but there is also the remote possibility

that you may need to slightly enlarge the

tremolo arm pass-through hole in your top

plate. Typically this extra step is not

needed, but we have seen on occasion where

it may be necessary. If you have performed the

above described procedure and are still

experiencing a tight tremolo arm the only

solution is to slightly enlarge the tremolo

arm pass-through hole in the top plate. You

will need a numbered (1-40) and a lettered

(A-Z) drill index sets to perform this

procedure the most effectively without over

enlarging the hole too much, fractional

drill indexes increase in size too much from

one drill bit to the next, numbered (1-40)

drill indexes increase only 0.001" to 0.007"

in size from one drill bit to the next

largest and lettered (A-Z) drill indexes

increase only 0.004 to 0.008" in size from

one drill bit to the next largest. For this

procedure the top plate has to be removed

from the tremolo block. Clamp the top plate

in-between two pieces of wood in a vise to

securely hold in in place, do not attempt to

perform this by holding the top plate by

hand. First thing to do is put on your

safety glasses to prevent eye injury and

then determine

which size drill bit just fits through the

top plates tremolo arm pass-through hole and

then select the next drill bit larger which

is probably around a #1 (0.228") which will

remove just a very small amount of material.

One you have enlarged the tremolo arm-pass

through hole in your top plate with the next

size larger drill bit re-install the tremolo

arm in the tremolo block and fasten down the

top plate and check for fit. If the tremolo

arm is still too tight then remove the top

plate and select the next size larger drill

bit from what you used previously and

enlarge the hole again, slightly larger.

Repeat as necessary, but you should not have

to enlarge the tremolo arm pass-through hole

in the top plate too much. When you

have enlarged the tremolo arm pass-through

hole adequately and if you have a 62 degree

countersink bit of about 3/8" in diameter

you may want to very gently use it to remove

the slight burr from the top and bottom

surfaces of the top plate that you created

by drilling out the tremolo arm pass-through

hole. Obviously since the top plate is

chrome plated by performing this procedure

will remove the chrome plating and you may

notice a slight copper color around the

surface of the top plate once you use the

countersink bit as a de-burr tool.

|