The

Black

Strat Project #1

Project Start: October 2008

Project Completed: January 31,

2009 |

|

July 4, 2011: In looking back over the last

2-1/2 years at this initial Black Strat® project a lot

of innovation and change has come about in the

production of our custom Black Strat® parts, kits and

assemblies. We've learned a lot along the way

in how to accurately replicate an authentic Black

Strat® pickguard assembly. Our current

production of Black Strat® parts and assemblies are

considerably more complex, unique and that much more

authentic to the original than the one depicted

below, but none-the-less, this project was the starting point that

lead us through many series of improvements,

enhancements and changes. Then with the purchase of

both the NOS and Relic version of Fender's Custom Shop

Gilmour Strat's, we now have a lot more insight for a

number of details that make the difference between a

simple knock-off and an accurate reproduction. We're proud to be able to

provide our customers with products that are the

most authentic in production outside of the Fender® Custom Shop. Take a look at our

Black Strat® Parts

page for a complete listing all of our updated and most

current designed

Black Strat® parts, kits and complete pickguard assemblies.

Black Strat

Electronics Analysis:

Be sure to read our detailed

technical comparison we performed with the Relic and NOS

Fender Custom Shop Gilmour Black Strat electronics in

relation to our custom Black Strat pickguard assembly.

Read The Full Article Here.

Seymour Duncan's Custom

Shop Hand Scatter-Wound "SSL-1C DG" Pickup -

Our relationship with the Seymour Ducan Custom Shop

begain in January 2012 where we

are began having this bridge pickup specially wound for

us which a lot

of you serious Gilmour Black Strat® builders have sought after. These are original,

authentic Seymour Duncan Custom Shop hand scatter-wound

pickups. These pickups are available

separately

or installed in our

Complete Black Strat® Pickguard

Assemblies. We are

having two versions of this pickup custom wound for us,

for full details on the two versions

read the full article

here.

|

|

Complete Project Build Components

- 2008 Fender® 1962 Re-Issue

MIJ Stratocaster® Body, Black

- 2008

Fender® 1957 Re-Issue USA Stratocaster® Maple Neck, 21 Fret, 7.25" Radius, Soft V

Shape

- 2008

Fender® 1957 Re-Issue Gotoh Vintage Style Tuning Machines

- 2008 Fender® 1962 Re-Issue Hot

Rod Strat Serialized Neck Plate

- 2008

Fender® 1962 Re-Issue Output Jack Assembly

- 2006

Callaham Vintage S Model Bridge Assembly w/Custom Super Short 4¼"

Tremolo Arm

- Seymour

Duncan SSL-5 Custom Staggered Bridge Pickup

- Fender® Custom Shop Custom '69 Middle Pickup

- Fender® Custom Shop Fat '50s Neck Pickup

- Black 1 Ply 0.090" 11 Hole Pickguard (Custom Routed For Mini-Toggle)

- Fender® Accessory Kit (White)

- Fender® Vintage Strap Buttons

- Fender® 5-Way Pickup Selector Switch

- CTS 250k "No-Load" Tone Control Potentiometers (Audio

Taper) [Quantity 2]

- CTS 250k Volume Control Potentiometer (Audio Taper)

- 0.022 uF 100 Volt 225 Series Sprague Polyester Orange

Drop Tone Capacitors [Quantity 2]

- Treble Bypass Filter (AKA Treble Bleed Filter)

- SPDT Mini Toggle Switch

- GHS Boomers 10-48 David Gilmour Signature Series Strings

- 2008 Fender® / SKB Hard-Shell Case

- Conductive Adhesive Copper Shielding Foil

- Dremel Rotary Tool Nose Piece Attachment For Routing

(Craftsman #53141)

- Hi-Speed 1/8" Straight Router Bit (Craftsman #53090)

- Custom Routing Jig For Mini Toggle Switch Hole Slotting

- Custom Stainless Steel Recessed Mini Toggle Switch

Mounting Bracket

- Miscellaneous Wire, Pickguard/Output Jack/Tremolo Cavity

Cover Screws & Felt Washers

|

In The Beginning...

Before OverDrive Custom Guitar

Works was even a gleam in my eye....

This Gilmour style Black Strat® project was simply built for my own personal

amusement and enjoyment, I had no idea it would be

the building blocks for a full blown dedicated Strat® parts resource in less than 3 months. But that is

exactly what happened in March of 2009, OverDrive

Custom Guitar Works was born...

Electronic

parts, pickguard and components all laid out prior to assembly. Seymour

Duncan SSL-5 Custom Staggered bridge pickup, Fender® Custom Shop Fat 50s

pickups (neck), Fender® Custom Shop Custom '69 pickups (middle), GHS Boomers

10-48 strings, Fender® white accessory kit, all black 1 ply 0.090" black vinyl

pickguard (with clear protective sheeting still affixed), Fender® 5-way

pickup selector switch, two CTS 250k no-load tone potentiometers, one CTS

250k volume potentiometer, custom stainless steel

mounting bracket for recessed mini toggle switch, SPDT mini toggle

switch (neck / bridge pickup mod.), tone capacitor. I swapped out

the "Seymour Duncan" white with silver logo'ed pickup cover that came stock

on the SSL-5 with a plain white Fender® cover in the final assembly.

Since each of the Custom Shop Fat '50s pickups in the set of three are

of different resistance and inductance the pickup designated "neck" (blue

dot) was the only one used out of this set for my neck pickup. The

set of three pickups in the Custom Shop Custom '69 pickups are all of the

same resistance and inductance so it made no difference which one was used

for the middle pickup.

|

|

The custom made routing jig/guide

(clear Acrylic) used for precise routing of the small elongated hole in

pickguard for the recessed mini toggle switch. Using the rotary tool

with the routing base attached the clear routing jig did not allow any

lateral movement of the rotary tool, it only allowed for forward and backward

movement required to create the slot. The pickguard is held securely

in place sandwiched in-between two pieces 3/16" thick 7" x 10" acrylic sheets

(free remnants at a local Tap Plastics) held tightly in place with four

6-32 mounting bolts which align with two of the perimeter pickguard mounting

screw holes and two of the pickup mounting holes. In both of the

clear acrylic sheets there is a 3/4" hole in the location where the slot

is to be routed to allow access of the routing bit on the top side and

clearance on bottom side. The actual jig itself is made out of 1/2"

square acrylic bar stock and held in place on the top sheet of acrylic

with "Acrylic Cement" which is a solvent type bonding agent that has the

consistency of water and is a applied with a hypo-type applicator.

The bond that the acrylic cement produces becomes as strong as the acrylic

itself for it literally fuses/melts the two pieces together.

This jig precisely aligned

the rotary tool/router in the correct position and orientation for routing

of the small elongated hole so when the mini toggle switch is mounted in

the stainless steel recessed mounting bracket

it would position the switch lever so it would protrude precisely centered

through this small elongated hole. It worked out great, when the

toggle switch is flipped in either the up or down (on) position the toggle

lever has approximately 0.030" of clearance between all edges of the slot...

Perfect!

Normally

when the toggle switch is in the up position, towards the pickups it is

in the OFF position, when it is down (ON) it selects or activates the neck

pickup. But of course this orientation of the switch can be which

ever way is most comfortable and desirable for you and your particular

playing style.

|

|

Close

up of the routing jig with a freshly routed pickguard still sandwiched

in-between. The pickguard pictured secured in the jig was the first

pickguard to be routed with this new routing jig and it worked out perfect.

All my calculations and measurements that went into constructing this jig

worked out exactly as expected and produced the desired slot length.

This new routing jig is a dream to use in routing these slots for the recessed

toggle switch, there's no guess work, everything is secure and the slot

can only be produced with the fixed length of 0.300" and the width of the

router bit of 0.125". When I decided to start selling these

pickguard's

pre-routed for this recessed mini toggled switch I figured it was best

to make a new and refined routing jig to streamline the process and help

eliminate a lot of the variables that could be easily introduced with my

original and very basic routing jig. The original jig worked fine

for my first personal project, but this one is so much better and accurate

for small scale production work.

|

|

The variable speed Dremel MultiPro

rotary tool I used for routing the small elongated hole (0.125" x 0.300")

in the pickguard for the recessed mini toggle switch lever to protrude

through for the neck and bridge pickup modification. I set the rotation

speed to approximately 8,000 to 9,000 RPM's which is just a little bit

faster than the lowest speed (5,000 RPM) this rotary tool is capable of

and no melting or chipping occurred indicating it was not too fast nor

too slow.

|

|

Close

up detail of the router nose piece attachment and the 1/8" straight router

bit. The 1/8" shank, 1/8" straight router bit is a Craftsman #53090.

|

|

Close-up of the pickguard

after the 0.300" x 0.125" elongated hole was routed out for the recessed

mini toggle switch lever to protrude through.

|

|

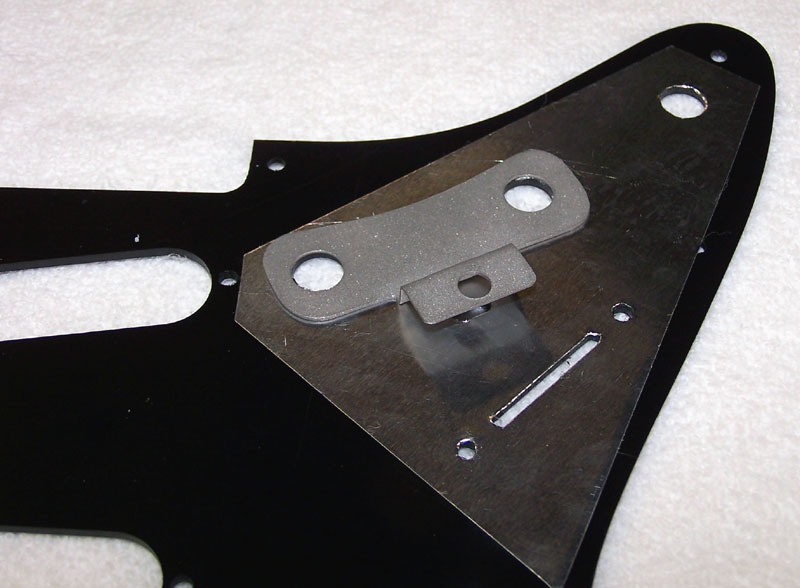

The rear side of pickguard with

the custom stainless steel recessed mini toggle

switch mounting bracket in the position/location as it will be mounted

and secured with the volume and tone potentiometers. After constructing

the recessed mini toggle switch mounting bracket all edges were cleaned

up by filing / grinding of all sharp edges and corners and then finished

up by bead blasting which produced the dull, flat and smooth appearance.

I chose to use stainless steel for this bracket for it's added stiffness

and ability to remain clean and not rust or oxidize through time as ferrous

steel would. Plus I had a few large sheets of this stainless steel

in stock in the shop from a previous unrelated project (darkroom sink).

The thickness of this bracket is 0.030" which allows each of the two securing

potentiometers to still have enough threads protruding through the pickguard

for adequate fastening with the mounting nuts without resorting to the

long shaft versions of these potentiometers. Pictured above is the

very first recessed mini toggle switch mounting bracket I made and it was

bead blasted after final grinding and filing of all the corners. Now I

polish them with a buffer instead of bead blasting, the end result no longer

looks dull and flat gray in appearance, they now take on a nice shine.

|

|

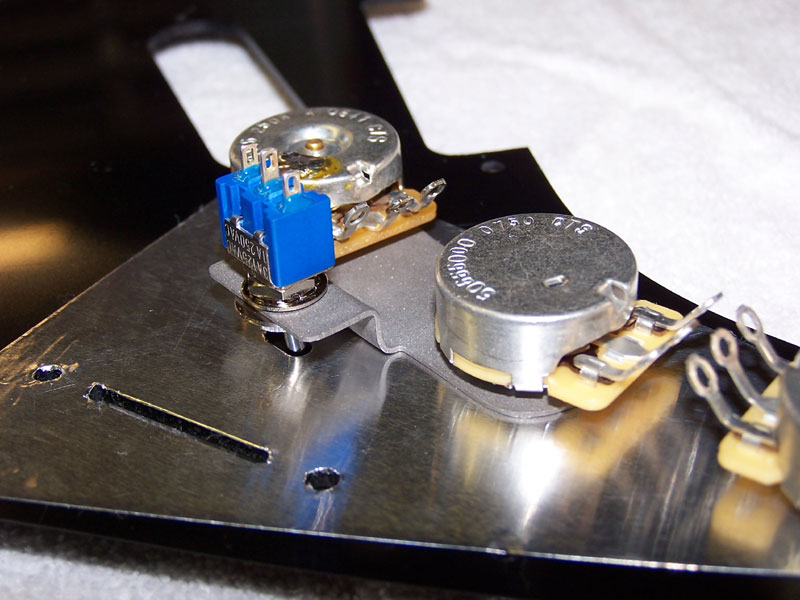

Rear side of the pickguard

showing the volume and tone control potentiometers mounted in place which

secure the stainless steel recessed mini toggle

switch mounting bracket to the pickguard.

|

|

Close up of the top side of

the pickguard just after installation of the volume and tone potentiometers,

the 5-way pickup selector switch and the recessed mini toggle switch.

Notice the very small amount of space to the left of the toggle switch

in-between the toggle lever and the edge of the elongated hole (approximately

0.030"), this same amount of space is the same on the opposite side when

the toggle switch is in the "On" position or flipped to the right as pictured

above. This small amount of space is ideal in order to keep your

slot for your toggle to protrude through at it's smallest possible size

and still allow for the full throw of the toggle switch without hitting

the pickguard when the switch is in either the on or off position.

|

|

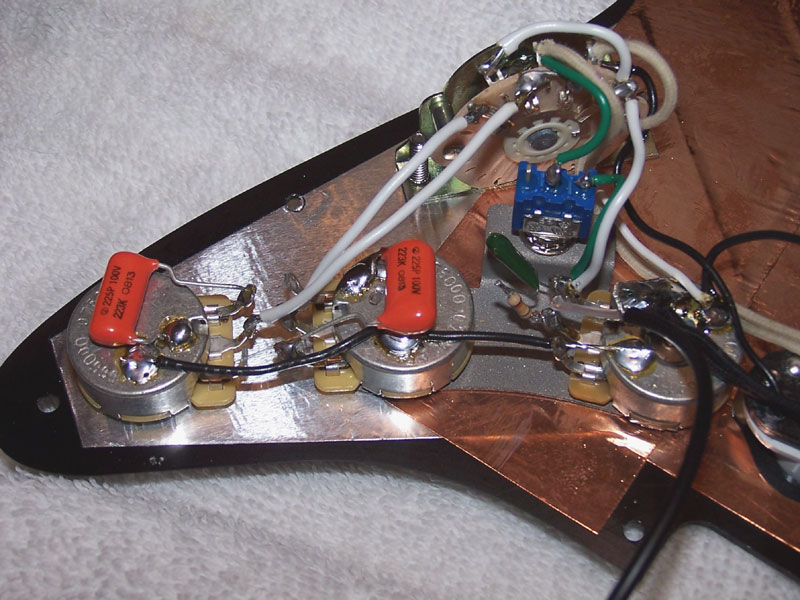

Close-up detail of pickup control

electronics after all wiring was completed. All connections were

done with 22 AWG hook-up wire with RG174/U mini coax for the main audio

lead from the output jack to the volume potentiometer which provides a

shielded central audio lead. In order for the Seymour Duncan SSL-5

to be in phase with the Fender® pickups when selected together the SSL-5

must be wired in reverse, the SSL-5's black wire connects to the selector

switch and the SSL-5's white wire connects to the ground (If you are using

all Fender® pickups then wire them all the same with the white wires connecting

to the 5-way switch and black wires to ground). Both of the no-load

tone potentiometers have their own Sprague polyester 225 series 0.022 uF

100 volt tone capacitor. I intend on swapping out the neck tone capacitor

with a 0.01 uF since the neck pickup needs less roll off of the high frequencies.

It's still a little experimental at this time but I feel that those two

tone capacitor values will suit me fine, just need to get her apart, again!

I have modified the tone potentiometer connections to the 5-way switch

to provide a separate tone control for both the bridge and middle pickup

and a separate tone control for the neck pickup. To achieve a tone

control for the bridge pickup you install a jumper wire between the two

inner most terminals on the 5-way switch on the side where the connections

from the two tone potentiometers connect (outlined below in the wiring

diagram). I have added a

treble

bypass filter on the volume potentiometer to help preserve the high

frequencies when the volume is rolled down.

|

|

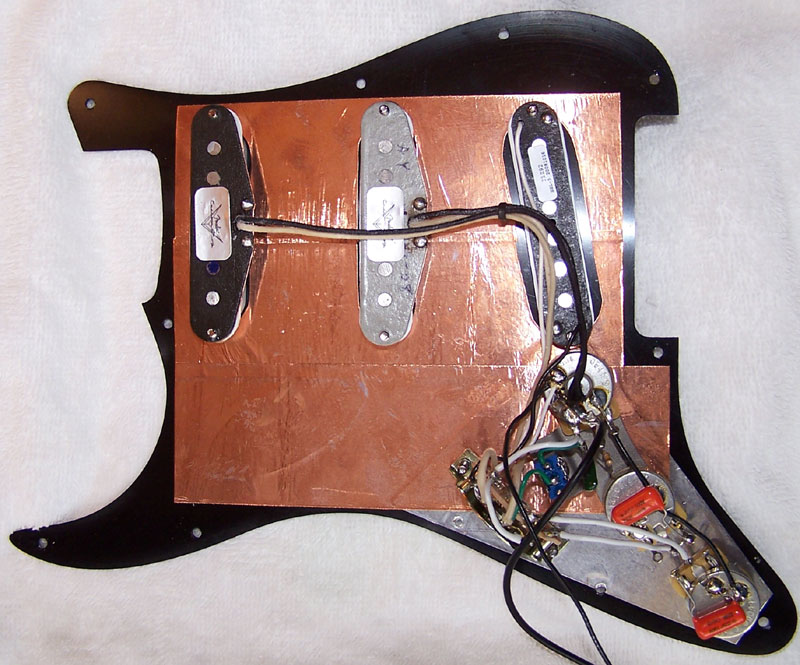

Rear of the pickguard assembly

showing the addition of the adhesive copper foil shielding to help reduce

noise from external sources. As the pickguard came from the manufacturer it only

had aluminum foil shielding in the pickup selection

switch and volume/tone control section. I completed the

shielding on the rear of the pickguard by the addition

of conductive adhesive copper foil. The adhesive on the copper foil shielding is conductive

so all overlapping pieces are conductive to one another. The two

lower holes in the pickguard's aluminum shielding make contact with the

two small copper foil tabs extending out of the body cavity shielding at

two of the pickguard mounting holes as pictured below.

|

|

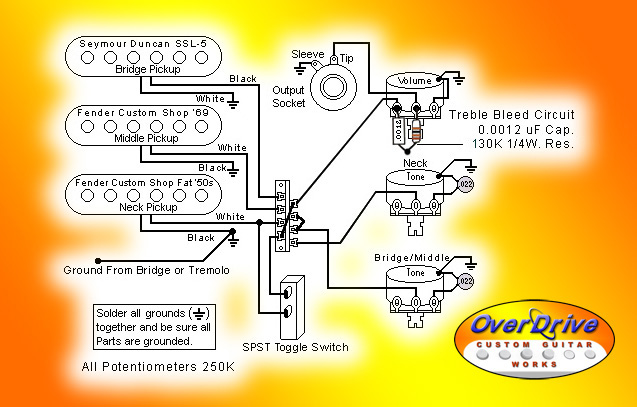

My Personal

Black Strat® Wiring Diagram

With SPST Mini-Toggle

Switch Modification To Activate Neck Pickup

Tone Potentiometers

are "No-Load" 250K Audio Taper

Volume Potentiometer

is a 250K Audio Taper

Wiring diagram with mini toggle

switch to activate neck pickup. When the mini

toggle switch is in the down position (as viewed with

the guitar in the playing position) the neck pickup is

turned on in parallel with which ever pickup(s) are

selected with the 5-way pickup selector switch. If

you have the 5-way pickup selector switch in position 5

(bridge) and mini toggle down (on) then both neck and

bridge pickups are active in parallel with each other.

If you have the 5-way pickup selector switch in position

4 (bridge and middle) and mini toggle down (on) then all

3 pickups (neck, middle and bridge) are active in

parallel with each other. In positions 3, 2 and 1

of the 5-way pickup selector switch there is no reason

to use the mini toggle switch (turn on) since the 5-way

pickup selector switch provides the remaining pickup

selections. Notice the small jumper wire on the

5-way pickup selector switch that connects the inner

most terminal connections on the 5-way switch on the

side where the wires from both tone controls connect.

This enables a tone control for both the bridge and

middle pickups. Each tone control in the above

diagram has it's own 0.022 uF capacitor. But by

installing different value tone control capacitors on

each tone potentiometer you can vary the amount of

darkening of your tone based on how much you turn the

tone control down. With values such as 0.047 uF

you'll loose treble from your tone quite quickly, using

values such as 0.01 uF you would loose treble more

slowly as you turn the tone control down. Since

the bridge pickup is intended to be a more brighter

sounding pickup you might just want a subtle amount of

tone control by using a 0.01 uF capacitor, this would

allow more rotation of the tone control before the high

treble rolls off, it would be a less sensitive

adjustment. This

is not an exact replica wiring diagram of "The" Black Strat, but performs

the exact same functions with the addition a few beneficial enhancements.

This is not the wiring diagram we provide with our "Black Strat® Parts Kits,

Assemblies

or Recessed Toggle Switch Brackets". They are more specific and true

to the original.

Based

on published information by Phil Taylor, David Gilmour's Black Strat® utilizes

a single .050 uF ceramic disc tone capacitor which works with both tone

potentiometers for neck and middle pickup tone control, it does not have the addition of the bridge tone control

modification and does not include a treble bypass circuit or utilize "no

load" tone potentiometers. These additional enhancements are what

I feel are beneficial and just make good sense.

IMPORTANT

NOTE:

If you are NOT using a Seymour Duncan pickup in the bridge position as

indicated above and using a Fender® pickup, then DO NOT

reverse wires on the bridge pickup connections, you would want to wire

your Fender® pickups all the same with the white wires connecting to the

5-way switch and black wires connecting to the ground.

IMPORTANT 2'ND NOTE: The above Important

Note does NOT apply to either of the two SSL-1C DG

pickups we offer, they are wound and polarized correctly

to match the two Fender Custom Shop pickups used in this

assembly.

|

|

After

application of the adhesive copper foil shielding in the body cavities

to help reduce electrical interference. Notice the two small copper

tabs in the upper portion of the picture, these tabs protrude over to the

pickguard mounting holes and make contact with the shielding on the pickguard

and when screwed in place it makes contact with the body cavity shielding,

pickguard shielding and ground.

Notice

in the lower portion of the photograph just right of center and in-between

the neck and middle pickup routing cavities. This is the location

of one of the factory drilled standard '62 pickguard mounting screw holes.

The '62 body has this one differently located mounting hole on an 11 hole

pickguard, and since the pickguard manufacturer I selected did not offer a pickguard with '62 mounting

hole patterns I simply drilled the one hole in the body just to the right

of it required to attach the typical 11 hole pattern pickguard. This

new hole is just to the right and up a small amount as viewed in the above

photograph. The hole I drilled was a lot cleaner with smoother light

countersinking

than the factory drilled holes. It's as if Fender® doesn't quite care

as much for surface finish of these holes since they will be covered by

the pickguard. If you'll notice the 6 bridge mounting screw holes,

they have nice clean factory countersinking quite similar to the hole I drilled

which is necessary to have a good clean mating of the bridge plate with

the face of the body to allow for smooth bridge rocking or tremolo use.

|

|

A

few close-up photographs of the back side of each of the pickups.

Neck Pickup

Fender® Custom Shop Fat '50s neck pickup. Notice the

blue dot on the one pole piece, second from the right,

this denotes this pickup as the neck pickup. Each

pickup in the Custom Shop Fat '50s set has different

characteristics and for them to be correctly identified

Fender® has color coded them. The bridge pickup has a

red dot and the middle pickup is simply silver with no

color coded pole piece but it is reverse wound for hum

cancelling in 5-way switching positions 2 and 4 and it

also has yellow and black leads indicating the reverse

winding.

|

Middle Pickup

Fender® Custom Shop Custom '69 pickup (middle position). Initialed

and dated by long time pickup winder Abigail Ybarra of Fender.

|

|

Bridge

Pickup

Seymour

Duncan SSL-5 Custom Staggered bridge pickup.

|

|

Something Special For

The Serious Gilmour Black Strat® Builder...

Seymour Duncan's Custom "SSL-1C DG"

Pickup

- We have limited supply of this

unique and rare pickup that a lot of you serious Gilmour

Black Strat® builders have sought after. These are original,

authentic Seymour Duncan Custom Shop hand scatter-wound

pickups. These pickups are available

separately or

installed in our

Complete Black Strat® Pickguard

Assemblies. Seymour Duncan's Custom "SSL-1C DG"

Pickup

- We have limited supply of this

unique and rare pickup that a lot of you serious Gilmour

Black Strat® builders have sought after. These are original,

authentic Seymour Duncan Custom Shop hand scatter-wound

pickups. These pickups are available

separately or

installed in our

Complete Black Strat® Pickguard

Assemblies.

|

|

The completed Black Strat® body assembly. Ready to go, ready to rock!

|

|

Back side of body showing

the 1 ply white vintage tremolo cavity cover.

|

|

Close-up

detail of the Callaham Vintage S Model Bridge Assembly. I used to have the bridge mounted with the top plate flush with the body of the guitar

(see note below).

It was not set up or adjusted to be free floating. You could only loosen

the tension of the strings with tremolo use. It's a good idea to

apply some melted paraffin wax to the threads on the 6 bridge mounting

screws to help lubricate them during installation into the body.

I installed the two outer most bridge mounting screws first (without any

tremolo springs installed) and screwed them in just until the rear of the

bridge started to rise off the body a fraction of an inch and then backed

them off just enough so the bridge sat flush back on the body. This

ensures that the bridge will sit flush with the body without and pressure

downward on the front edge of the bridge with the two outer mounting screws.

I then installed the remaining 4 inner bridge mounting screws down to a

point of about 1/32 of an inch from the top plate for stability.

Once all 6 screws were in place I installed the tremolo arm and rocked

the bridge back and forth (without tremolo springs) to check for ease of

movement and for any binding of the mounting screws. It was nice

and smooth, no binding at all. You want your bridge to be free of

any binding or friction on the mounting screws to allow for smooth tremolo

use and tuning stability. The three tremolo springs were installed

and adjusted/tensioned to provide just enough back pressure on the bridge

to retain tuning stability and to keep the rear of the bridge flush with

the body, but when you use the tremolo arm it does not take much pressure

to lift the bridge. The tremolo springs are tight enough to not allow

any bridge lift during extreme string bends. There is that happy

medium of tremolo spring adjustment to allow easy tremolo use but still

stay stable in tuning. Of course all tremolo spring adjustments are

performed with the stings installed and tuned to playing pitch.

October 23, 2009:

I have since made an adjustment to the bridge on my

Black Strat® to have it set up as "Free Floating".

I feel that it is much smoother and are able to

achieve a more subtle tremolo effect. With it

mounted flush you are required to have some amount

of excess spring tension to retain the top plate of

the bridge flush with the body and the initial

amount of pressure required on the tremolo arm to

break the bridge free from sitting flush with the

body does not allow for smooth tremolo use.

With it free floating about 1/8" off the body you

then have the ability to increase tension on the

strings as well as loosen (raise or lower pitch).

For those of you purists (or

whatever they might consider themselves) who noticed and

made mention of the saddle height adjustment set screws

on the B and E string saddle being a bit long and

installed wrong.... No, they were not installed

incorrectly! This has been pointed out that those

set screws belong on the G and D saddles, but that's

just how they came from Callaham, and I really didn't

give them much thought or notice at the time of

installation, besides, they have since been replaced

with appropriate length set screws. I just don't

get why certain people just have to insist that one must

be ignorant or don't know what they're doing by having

such a small amount of extra height with a couple set

screws, and could cause such a fuss, I just don't get

it..... It's a non-issue. I guess it just comes

down to that no matter what you do, someone will go out

of their way to look for things to find fault with, and

will be most certain to point it out. I've heard

of this "constructive ctitisizm" thingy, but just being

an ass is a different story.

|

|

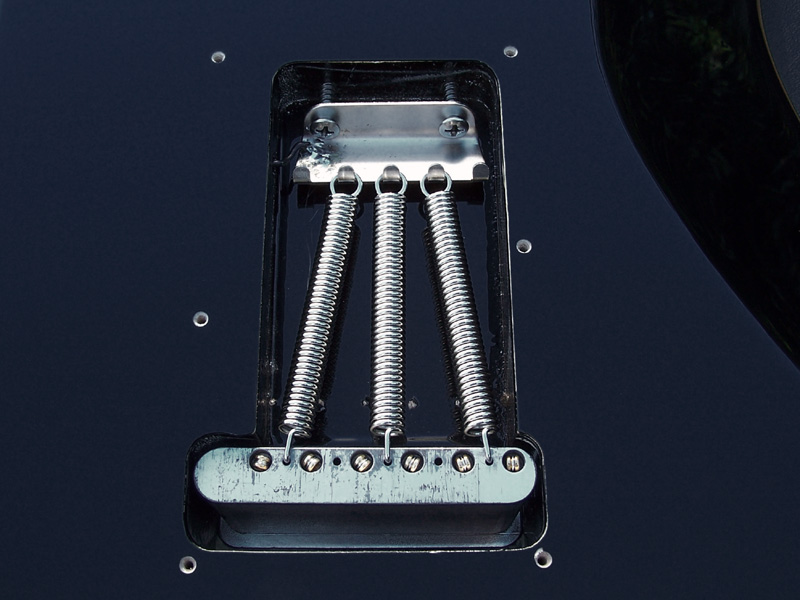

Tremolo

cavity, Callaham bridge block, tremolo spring claw and tremolo springs.

I prefer to have 3 springs installed, any more than that makes smooth tremolo

use more difficult. A grounding wire is soldered to the tremolo spring

claw and is inserted through the hole in tremolo cavity and passes through

to the electronics cavity on the front (top) side and is soldered to the

volume potentiometer case along with the other ground wires.

|

|

Heel of the 2008 '57 Re-issue

21 fret maple neck and the Fender® Custom Shop Fat '50 neck pickup.

|

|

Callaham

Vintage S Model Bridge with the Super Short 4-¼" tremolo arm.

Seymour Duncan SSL-5 bridge pickup and Fender® Custom Shop '69 middle pickup.

|

|

Close up detail of top side

of the body, controls, pickups and Callaham Vintage S Model Bridge Assembly

with the Super Short 4-¼" Tremolo Arm.

|

|

Another

close up detail photograph of the top side of the body from a different

angle.

|

|

The 2008

'57 re-issue Fender® USA 7.25" radius 21 fret "V" shape maple neck.

Also showing the 1957 vintage re-issue Gotoh tuning

machines, Fender® spaghetti logo and the single string tree. Notice

the blackening in the string slots in the nut, this is the product called

"Slick Nutz" which is a liquefied graphite that assists in smooth string

movement during tremolo usage or string bends and helps the strings return

to correct pitch. Slick Nutz is applied as a thick liquid for ease

of application but soon after the moisture evaporates and the lubricating

graphite remains.

|

|

The 2008

'57 vintage re-issue Gotoh tuning machines from the rear of the head stock.

If building this project again or if I was to replace the tuning machines

I would go with the Kluson SD9105MN nickel tuning machines instead of the

Gotoh, I feel they are better tuners. I've got a set of them in stock,

I might change them out at some point down the road....

|

|

Close-up detail of the 2008

'57 re-issue Fender® USA 7.25" radius soft "V" shape maple neck at the 12'th

fret. It has a superb nitrocellulose lacquer finish throughout!

The USA '57 re-issue necks are very nice and don't compare to the newer

American Standard maple necks. The frets are vintage style so they

are smaller than the medium-jumbo frets you'll find on newer Strat's.

The '57 re-issue necks have 21 frets.

|

|

Fender® vintage serial numbered

neck plate. When installing the 4 neck joint screws it is wise to

apply melted paraffin wax to the threads to ease and lubricate installation.

Easy way to do this is to simply warm up the screws and touch them to the

block of wax. When the warm screw touches the wax it melts and adheres

to the screw threads. You don't need much, but it is better than

dry screws. You might notice this wax on factory installed screws

when you remove them, especially the larger ones.

|

|

Nestled

in for a warm nights sleep in the Fender® SKB hard shell case.

|

|

Final

Notes Of The Black Strat® Build Project:

I designed

and constructed the small see-through (clear) routing jig to route the

small elongated hole for the recessed neck pickup toggle selector switch.

Sure, I could of simply drilled a large enough hole to allow for amount

of space needed to accommodate the range of throw this mini toggle switch

exhibits as it is recessed, but that would of put a 3/8" circular hole

which would of looked terrible with the recessed toggle protruding through,

you would be able to see directly into the pickguard and see the base of

the toggle switch and it's chrome locking nut and washer. I feel

that the 0.125" x 0.300" slot is much more desirable and visual appealing.

I also could of simply mounted the toggle switch as it was designed with

the small chrome washer and hex nut securing it on the top side of the pickguard

(panel mount style/method), but that would simply look bland and typical

and then the toggle lever would protrude approximately 1/2" to 3/4" above

the pickguard surface and could be easily switched unknowingly by a simple

bump of the knuckle. It may seem like a lot of work for such a small

feature, but I am a perfectionist (not always a good thing) and always

enjoy a challenge, and sometimes it's the small things that make the difference

between average and truly custom.

I also

designed and constructed the small stainless steel bracket that mounts

between the volume and neck tone control to secure the recessed mini toggle

switch.

After

initial construction of the guitar the following adjustments were performed:

- Each slot

of the nut was "cleaned-up" ever so gently with appropriate sized nut files

to allow for smooth, non-stick movement of the strings during tremolo action.

- Slick Nutz graphite was applied in each of the string slots of the nut

to provide nice smooth movement of strings through nut slots, Slick Nutz

graphite was also applied on the underside of the string tree to reduce

friction.

- Removed

the neck to make a truss rod adjustment for neck relief (twice).

- Adjust

each bridge saddle height for comfortable string height/action.

- Adjust

each bridge saddle for proper intonation.

- Adjust

each pickup height for balanced output.

- Adjust

tremolo spring tension to provide nice and smooth "free floating" tremolo action.

In Summary:

At the time of

this writing I've

custom built 8 completely unique Stratocaster's during the last 5 years

and I'd have to say that at this point this Black Strat® is the most satisfying with it's overall

sound quality, playability and visual appeal... This project

Strat® will remain as one of my favorites. It has a stark beauty all

it's own. Simply put, it is a dream to play, it sounds beautiful,

plays smooth and lends quite well to the creativity that comes from an

instrument that molds to you as one, and this is where musical creativity

can truly begin....

The

total cost of this Black Strat® is based entirely on already possessing the necessary tools for

assembly and setup, such as:

-

Dremel

hi-speed rotary tool.

-

Soldering

iron.

-

Solder.

-

22 Gauge Wire.

-

Wire cutters/strippers.

-

Assorted

sized Phillips and slotted screwdrivers (PH1 & PH2).

-

1/4" drive

socket set.

-

Hex wrenches.

-

Feeler

gauges.

-

6" stainless

steel rule graduated in 1/64" increments.

-

Capo.

-

Electronic

tuner.

-

Possibly

more that has escaped me for now....

If you

do not have any of these tools, parts or accessories already in your possession

your cost will be more. Price also depends on the source you acquire

your parts from and the quality level of the parts you choose for your

build project. One can always acquire lower quality or imported parts,

but remember, often you get what you pay for...

You

will also need a good working knowledge of the entire guitar setup and

assembly procedures, how to read a wiring diagram or schematic and how

to solder efficiently. You should also be proficient with using the

hi-speed rotary tool in order to accurately route the small elongated slot

in the pickguard for the mini toggle switch lever.

November 10, 2010:

In pondering whether or not to sell this guitar I came

to the realization that this single prototype Black

Strat® launched my business and one that is doing quite

well and growing nicely, and if I was to sell it, at

some point in time on down the road I'd probably be

kicking myself and wondering why the hell did I sell it,

it is the foundation of my business beginnings and

launched a desire to build the best Black Strat® replica

pickguard assembly you will find anywhere... So I

think I'll hang on to this guitar, it'll always bring

back memories of a time before OverDrive Custom Guitar

Works as well as a time that began it all...

April 7, 2011:

While reviewing this page this evening, specifically

looking at my wiring, I realize how much my wiring

skills have evolved and improved in the last 2-1/2 years

and when I look at the wiring of this particular project

I cringe at the thought of how ugly my wiring job was

back then. I guess after building hundreds of

these electronics assemblies you perfect your procedures

and methods and all by logic, you "should" get

better..... And I'm happy to say that I have....

Much better!

I will

continue to update this page as more detailed or subtle build information

comes to mind. The current revision date is found at the very top of this

page, if the date has changed since

the last time you visited then new information/revisions or updated photographs

have been added.

Do you have

a comment, question, suggestion or recommendation?

Please drop us a line, we'd love to hear from you.

|